Motion CompensatedFeedering of CoiledTubing Reel forEquinor

Posted on 03/07/2023 at 16:50

Demonstrating the excellence of the T700

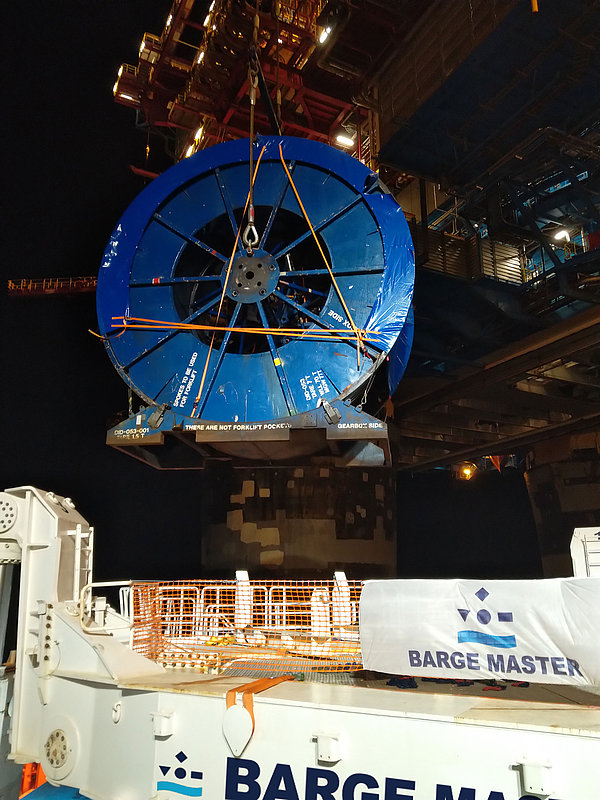

Barge Master recently completed a project for Equinor, demonstrating the capabilities of their motion compensation platform, the T700. The platform served as a reliable feeder base for the lift of a coiled tubing REEL. By employing the T700 platform, Equinor was able to enhance the operational efficiency of their platform crane by expanding the lifting weather window through compensating vessel motions.

Equinor required assistance in lifting a 40-ton coiled tubing REEL from Schlumberger to their Gulfaks C platform, since the weight of the REEL exceeded the platform crane’s capacity. To overcome this, Barge Master’s motion-compensated platform was employed, effectively reducing the Dynamic Amplification Factor (DAF) of the crane and enabling a successful and safe lift within the crane’s limitations.

Enhancing safety and decreasing downtime

For this project, the Sølstad vessel Normand Ferking was selected, and the T700 was mobilized in Rotterdam, the Netherlands. Subsequently, the vessel set sail to Tananger, Norway, to mobilize the Coiled Tubing REEL. Next it ventured into the challenging weather conditions at the Gulfaks C platform, where the lift was executed safely.

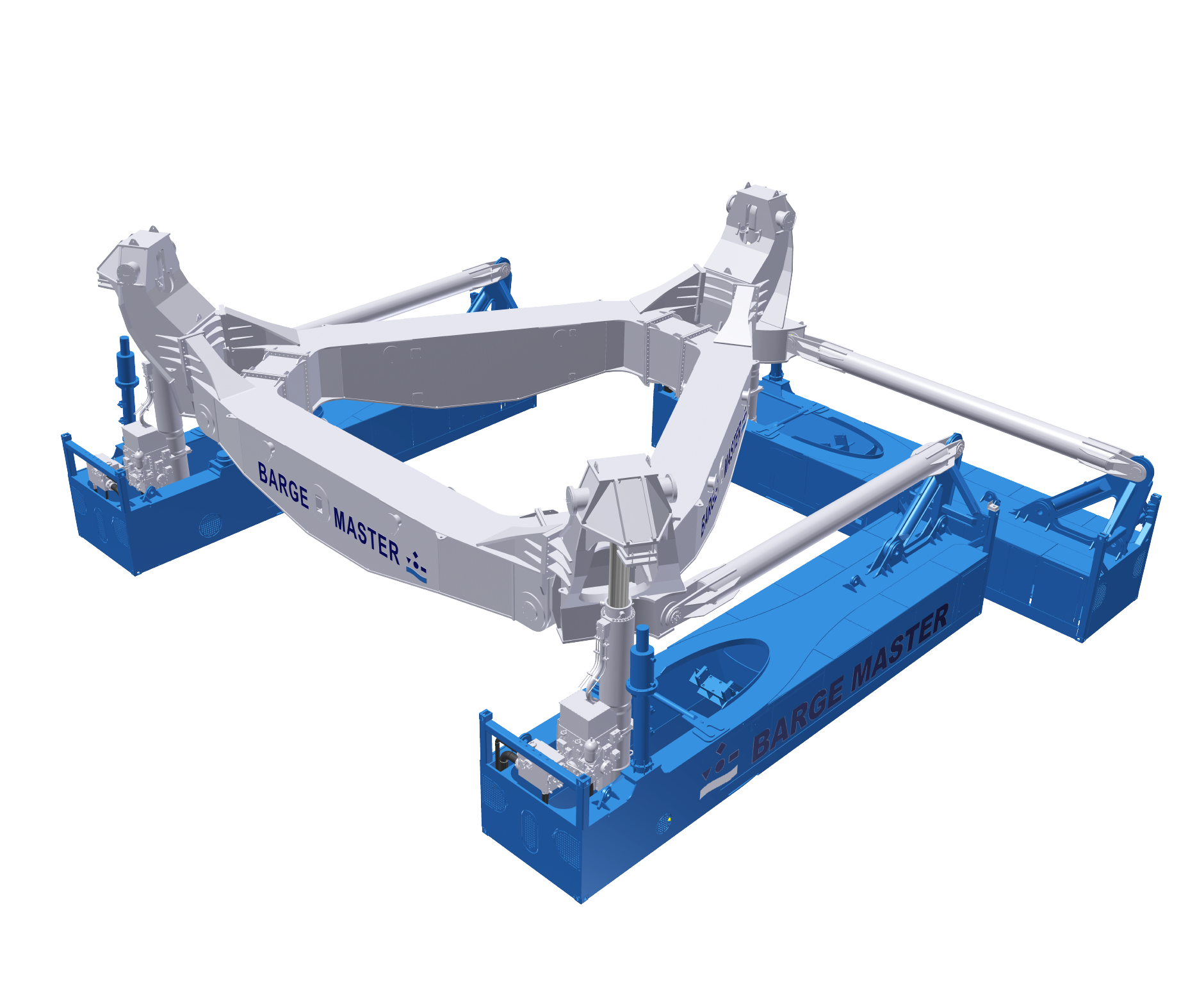

This project highlights the versatility and potential of motion compensation as a feeder base, enabling the utilization and enhancement of existing equipment. The T700 is capable of compensating the roll, pitch, and heave motions of loads weighing up to 700 tons, in sea states of up to Hs 2.5 meters. It is a fully containerized system that can be easily transported and mobilized on any vessel or barge.

Barge Master sees the potential of this application for a wide range of projects and continues to develop new and smarter solutions for this particular business case